- June 13, 2022

- Posted by: Stef Lantin

- Category: Research Spotlight

Math2Market and its GeoDict software for modeling and simulation of material microstructures and prediction of material properties

By Barbara Planas & Andreas Wiegmann

Math2Market GmbH develops software for simulating anything from subprocesses of manufacturing chocolate to crude oil production, allowing for engineering design of porous and composite materials as well as predictive capability involving multi-physical processes. Here, we give an overview of how it all started, where we are positioned worldwide in simulation-related activities for the porous media community, and provide examples of what our software can currently do as well as where it is going in the future. This list of currently 538 publications by Math2Market’s clients and employees gives an impression of all the scientific work that can be done and has been done with GeoDict.

Math2Market GmbH started in September 2011 as a spin-off from the Fraunhofer Institute for Industrial Mathematics (ITWM in German) in Kaiserslautern, Germany. Since then, we have grown to be a global leader in digital solutions for porous microstructures and composite materials research and development. The genesis of our software GeoDict, the digital material laboratory, goes back to the year 2001. Since then, the functionality was expanded in directions based on the needs of our users.

Our team of highly qualified engineers and scientists provides reliable software support as well as direct assistance in complex material research and material development issues. Today, Math2Market employs over 50 people at the Kaiserslautern location and forecasts income of over € 6 million in 2022.

Figure 1. Research and development of battery materials directly on the computer.

GeoDict, Math2Market’s star software product:

The GeoDict® simulation software combines cutting-edge research and powerful software development into a user-friendly solution that digitally maps the entire materials development workflow. Using artificial intelligence, GeoDict® enables precise characterization and analysis of a material’s microstructure, as well as reliable prediction of material behavior under differing conditions through simulation. The users change the microstructural design of materials directly in the computer and optimize them by modifying models interactively.

For industrial applications, GeoDict represents a superb time- and cost-saving alternative to traditional prototyping and greatly accelerates the analysis, design, and testing of materials. In addition, the strictly mathematical-physical conception of the calculation principles allows deeper insights into the behavior of the material which, in many cases, is not readily obtained from laboratory tests.

Figure 2. Extensive range of applications of the GeoDict software: Digital Rock Physics, Batteries & Fuel cell materials research, Filter and Filter Media engineering and research, Digital Materials, and more.

The following are examples of porous materials and related processes that can be currently simulated with GeoDict:

- Filter media, filter pleats, filters, membranes, catalysts, gasoline particulate filters and diesel particulate filters; Simulations of flow and coalescence of liquid particles in gas flow, electrostatic effects induced by charged fibers and charged particles, as well as multiscale advection-diffusion-reaction processes are commercially available and continue to be actively developed. More information can be found here.

- Battery materials (cathodes, anodes, separators, etc.); Charging simulations and damage / aging, fuel cell transport layers (gas diffusion layers, microporous layer, catalyst layer) including two-phase flows and channel design. Computation of the thermal and electrical conductivity from the microstructure and simulation of the infiltration process with electrolyte. More information can be found here.

- Composites, foams, ceramics, etc.; Digital material geometry model development, numerical methodology development and software development including large deformations of porous media, single-phase and two-phase flows through porous media, thermal and electrical conductivity. More information can be found here.

- Rocks; i.e. the characterization of reservoir rocks based on Synchrotron or micro-CT scans by Digital Rock Physics and Digital Rock Analysis. This includes the image processing and image analysis for sandstones, carbonates, and shales, to determine representative elementary volumes of these types of rocks. From the three-dimensional microstructure of the rock, the unresolved porosity, absolute permeability, forced imbibition, and precipitation/deposition and all Archie parameters can be computed. Recently, the microstructure modelling and property simulations capabilities are receiving attention from our clients regarding Carbon Capture Utilization and Storage. More information can be found here.

- Personal care products like diapers and wipes, paper manufacturing materials such as forming fabrics and paper dewatering felts, sound absorbing porous media thermally insulating porous media; improving manufacturing processes, engineering design. More information can be found here.

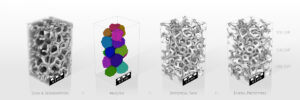

Figure 3.: Schematic representation of modeling and simulation for research and development of open cell foams.

The central ideas behind the GeoDict software:

It revolutionizes the traditional research and development approach for designing the microstructure of existing and new materials, based on the following central ideas:

- The microscale morphology of materials determines their macroscopic properties to a large extent.

- 3D scans (Synchrotron tomography, µCT, FIB-SEM, etc.) provide enough information about the material’s microstructure

- if the resolution is fine enough and

- if the field of view is large enough (REV).

- Microscale simulations on scans match results of microscale and macroscale physical experiments on the real materials

- if the right physical equations are used,

- and if these equations are correctly discretized (by finite volumes),

- and if the resulting large systems of equations are solved correctly,

- and if the individual constituent materials are properly identified (labeled) in the scan, for example oil and water phases in the pore space

- and if the properties of the individual constituent materials are known, for example density and viscosity of the various fluids and the slip length on solid surfaces.

The collective information derived from 3D scans for individual objects in it is called a Digital Twin of a material. For example, a straight fiber with circular cross-section can be represented by 2 endpoints and a diameter, and the data for all fibers in a scan make up the twin. We think of such representations of objects as GAD (GeoDict analytic data), like the classical CAD models for macroscopic classical devices. Because material morphologies are usually random, most CAD tools do not apply to material microstructures. To fill this gap, GeoDict contains statistical models for many types of materials, as well as code parts that we refer to as Structure Generators. Structure Generators create 3D geometric models (Realizations) from the models and parameters and are randomized by also depending on a so-called random seed. By varying the random seed, the individual microstructure changes completely, yet statistically it is always the same. The generated Realizations are in the same file format and internal representation as segmented 3D scans.

GeoDict also contains built-in solvers for partial differential equations. Due to the similarity of the representation, these solvers can be applied both on segmented scans of existing materials and on generated 3D models of possibly not-yet-existing materials. GeoDict solvers run directly on uniform Cartesian structured meshes (called voxels) defined by the scans, so that no labor-intensive manual meshing is required. Some simulations on scans, together with the scan time and image processing time, are already faster and cheaper than corresponding physical experiments on the real materials.

GeoDict can also determine the input values for Generators from scans by performing statistical analysis on individually identified components of the material, i. e. the GAD information. For example, for a fibrous filter media, the individual fibers can be identified by Artificial Intelligence, where the challenge lies in separating fibers at their touching points [1]. We refer to the stochastic model, together with a particular choice of input parameters and their distributions, as statistical Digital Twins. For statistical digital twins, properties simulated on their realizations match physical experiments performed on the real material. By varying the random seed to create materials randomness in the digital experiments, also variations of the simulated effective macroscopic properties occur. This is due to the same effect that cause variations in the detailed results of real experiments when they are performed on small samples. The sample size must be large enough to be representative. If the imaged or generated domain is large enough, the effective properties become almost the same for all scans of the same material or realizations of the same model.

Finally, digital material design using GeoDict finds better materials without the need to manufacture them. Statistical Digital Siblings are derived from the statistical digital twins by modifying the input parameters to the statistical models. To recap: a digital twin comes from a scan, the statistical digital twin is a model that agrees statistically with the twin. The latter has the advantage that it lets the user design and optimize novel materials in the computer by varying meaningful statistical properties like the porosity, fiber diameters or fiber orientation.

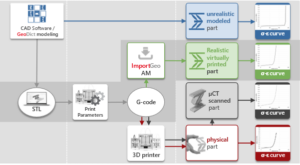

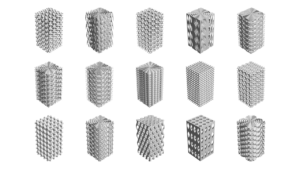

We are also very excited about one of our more recent advances, using GeoDict to provide solutions in the field of additive manufacturing (AM). AM uses computer generated geometric objects for 3D printing, allowing direct production of 3D microstructures that can be designed and optimized using GeoDict. Modelling triply periodic minimal surfaces (TPMS) and lattices is now possible. Soap films are well-known examples of minimal surfaces, that get their name from the property that they are locally area-minimizing. Particularly useful are minimal surfaces that repeat themselves in three dimensions. These are called triply periodic. In additive manufacturing, the ideal surface gets thickened into a printable volume. The design of heat exchangers was recently revolutionized using TPMS. Both TPMS and lattices are very interesting porous materials because they can have rather high porosity and have well-defined effective properties. As 3D printing is not perfect, GeoDict also permits simulations of the 3D printing process to produce statistical digital twins that capture artefacts induced by imperfections of the printing process. These can be used to predict effects of defects.

GeoDict has a wide variety of users, from university departments to some of the largest corporations in the world. To meet our clients’ requests and needs, GeoDict runs on a wide variety of platforms, including workstations, clusters and in the cloud. We look forward to meeting the porous media challenges of the future.

[1] Proceedings of Filtech 2019, Session F9 – Filter Media – Modelling, Artificial Intelligence, Machine Learning https://filtech.de/conference/conference-archive/;

Full paper: https://doi.org/10.30423/report.m2m-2020-01]

Figure 4.: Simulated and measured mechanical properties of a printed part agree when simulations are performed on the segmented µCT scan or when the printing process is considered. They do not agree if the CAD drawing is used in the simulations directly.

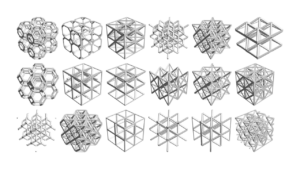

Figure 5.: Examples of strut-based porous media or lattice models in GeoDict. For more details see here.

Figure 6.: Examples of triply periodic minimal surfaces (TPMS) or functionally generated porous structures in GeoDict. For more details see here.